Real-time management is the ultimate challenge for supply chains. In the case of critical equipment in the medical or aerospace industry, real-time capacity becomes a top priority because of the equipment value or due to the critical delay to access this equipment.

Traditionally, organizational methods and best practices assisted by effective communications between resources were the only way to solve logistical challenges. In fact, although usually effective, there comes times when these solutions are ineffective, unreliable and even create dangerous situations. Nowadays, technological solutions can support or even replace these good practices.

Real-Time Positioning

To illustrate this point, let’s take the example of managing known critical equipment: an oxygen bottle for medical purposes. The same reasoning can apply to stretchers, heavy equipment for construction, cars for dealers, etc.

After handling it, the unused oxygen bottle must be replaced in the right place in order to:

- not disrupt the next planned operations;

- allow the next user to quickly find it in an emergency;

- be able to know its state and fill it in if necessary.

The correct storage location or the condition of the oxygen bottle may or may not be known to all employees who will handle it. A dedicated warehouse, for example, may be close to some users and far for others. A lot of travel time is expected for hospital staff to simply put the equipment in the right place. This precious time can certainly be put to better use such as patient service and support for loved ones.

What if a technology could reduce travel time, even eliminate unnecessary travel? Every staff member requiring an oxygen bottle would be able to know the position of critical equipment at all times. Anyone could access it quickly. Since the location of the equipment can suddenly be distributed in the hospital, the equipment is more likely to be closer to the staff than the warehouse.

Managing Critical Equipment in Real Time

Does this scenario ring any bells? Does the following questions have any value to you? If so, asset management systems or “real-time location system” can probably solve some of your problems:

- How many of a certain type of equipment is on the site now?

- Is there someone trying to steal equipment? Or to use it on another site?

- Precisely, where is the equipment now?

- What is the trajectory of the equipment and how can the efficiency and fluidity be improved?

- What is the temperature, humidity, air quality near this equipment?

- Is it valuable to have an alert when a temperature is exceeded?

- Is it valuable to have an alert when equipment leaves the site

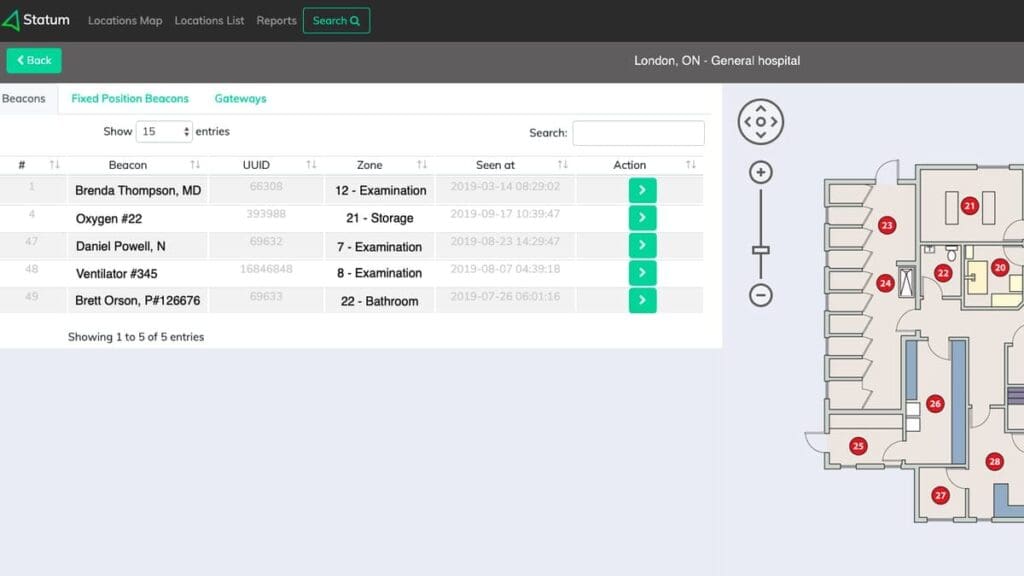

The answer to these questions is accomplished through the many features of the STATUM asset tracking solution:

- Real-time inventory

- Geo fencing

- Micro geolocation

- Site positioning history

- Environmental Parameter Measurement for each equipment

- Notifications

In the end, the choice is quite simple. Conventional inventory management techniques, although effective, have their limits. The addition of real-time management technologies brings tangible benefits from the moment of installation and, depending on the context, the impacts can be:

- Saving a Life

- Avoiding theft of equipment

- Avoiding loss of equipment

- Saving time

- Saving money

- Gaining efficiency

- Do more with Less

You get the point. What are we waiting for?

You have an idea for a project and need our expertise to achieve it?

Contact our experts!